Prime Scientific - Waste to Energy Conversion. How Microwave Assisted Pyrolysis Units Can Generate Clean Energy

Waste-to-energy is the process of generating energy in the form of electricity or heat from the primary treatment of waste.

The conversion of biomass and waste into energy has been one of the priorities of the UAE government during the past years and this is why the project of BEEAH has been established to enable the production of power from landfill and waste to provide clean energy which is in line with the government's initiative to promote Environmental and Clean Energy to the UAE.

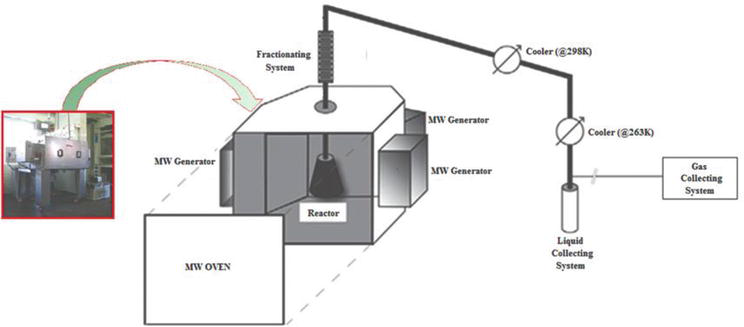

One of the methods to produce energy from waste are pyrolysis units which use microwave assisted pyrolysis to produce fuel from biomass and plastics.

Microwave Assisted Pyrolysis

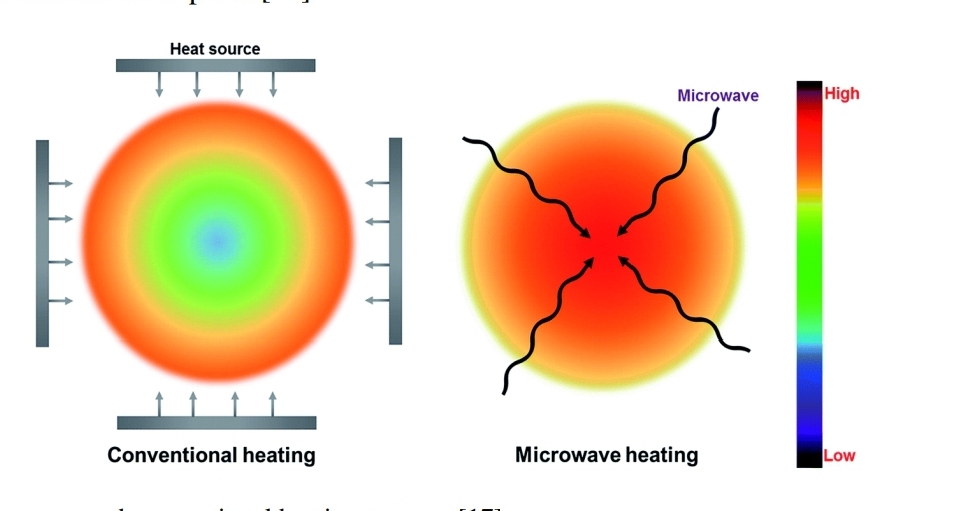

Microwave-assisted pyrolysis is an energy-efficient and controllable way of converting the feedstock to chemicals or fuels. Microwave heating has a number of advantages over conventional types of heating including the selective activation of various chemicals.

This is because microwave energy is directly absorbed by the molecules that are able to absorb the exact energy of the wavelength which is emitted by the microwave.

Heating by conduction or convection is different because the entire surroundings or immediate contact surfaces are heated due to the transfer of thermal energy from one medium to the other. However, microwave energy offers selective heating of molecules through the absorption of energy emitted from the microwave.

An example of selectivity is biomass pyrolysis. The principal components of the biomass such as hemicellulose, cellulose, and lignin are activated at different temperatures. This makes it possible to increase the selectivity of the bio-oil, collecting different fractions at different temperatures. Moreover, the thermal degradation of polysaccharides proceeds at lower temperatures compared to the conventional methods.

How Does Microwave Pyrolysis Work?

Pyrolysis is a process that involves thermochemical breakdown of organic material at elevated temperatures 300-900°C in oxygen free environment, resulting in oil and gas yields with char as the solid residue. Based on heating strategies, pyrolysis can be classified as

conventional pyrolysis and microwave assisted pyrolysis. The former involves surface heating of plastic waste using fuels like coal, whereas the latter works on the principle of microwave electromagnetic radiations conversion to thermal energy and has the potential

for volumetric heating which is faster as compared to surface heating.

Major biomass structural components are solid oxygen-containing polymers. Microwave irradiation very efficiently interacts with these materials reducing their temperature decomposition compared with conventional pyrolysis. At the same time, most pyrolysis products (except biochar) are gas or volatiles.

Due to the low density of these products, microwave irradiation weakly interacts with them, leaving gas and volatiles compounds at a temperature lowest than during conventional heating. Furthermore, obtained biochar is non-conductive, low-polar, and does not interact with MW irradiation.

Compared to conventional pyrolysis, which uses electric resistance heating, microwave pyrolysis heating is much more efficient because of rapid volumetric heating

Benefitsof Microwave Pyrolysis

Pyrolysis using microwave has several benefits over conventional pyrolysis with respect to the production of biooil as well. The biooil produced from microwave pyrolysis of sewage sludge was much cleaner than the biooil produced from conventional pyrolysis because it had no harmful compounds such as heavy polycyclic aromatic compounds.

The microwave pyrolysis of rubberwood performed by Halim and Swithenbank (2016) resulted in higher biooil yields and lower oxygen content (~35 wt.%) than conventional slow pyrolysis (43–45 wt.%). This significantly improved biooil quality is due to microwave pyrolysis’s rapid heating and quenching characteristics.

Conclusions

Though the method is suitable, it still requires extended studies to develop proper control in getting the optimum yield and specific composition of products.

Although, the initial capital cost of

microwave system is high, this can be offset by economic benefits attained in operation by process time-savings, the yield of saleable by-products and environmental compatibility

References

1. https://www.sairem.com/solutions-for-research-and-development-laboratories/microwave-assisted-pyrolysis/

2. Microwave assisted pyrolysis of plastic waste for production of fuels: a review. MATEC Web of Conferences 131, 02005 (2017)

3. https://www.sciencedirect.com/topics/engineering/microwave-pyrolysis#:~:text=Compared%20to%20conventional%20pyrolysis%2C%20which,et%20al.%2C%202015).

Prime Scientific

Prime Scientific provides equipment, instruments and other related products and materials. We aim to be a one stop shop for all our customers laboratory needs. Since 2001, Prime has strived to provide the best services and solutions to the scientific community in the region.

No comments yet. Login to start a new discussion Start a new discussion